“Ensuring excellent product quality is the essential motivation of microbiological quality control in breweries of all sizes. Fast and simple molecular biological methods can be an extremely useful tool in any brewery’s toolbox!”

Simple Detection & Characterization of Beer Spoiling Bacteria

From microbiological perspective, breweries have various critical points where microorganisms can negatively affect product quality. Therefore, raw materials, product intermediates, end products, surfaces and special areas are frequently monitored in terms of hygienic control procedures. Breweries invest a lot of time, energy and money to ensure microbiological stability of their beloved beer in order to protect their label and reputation.

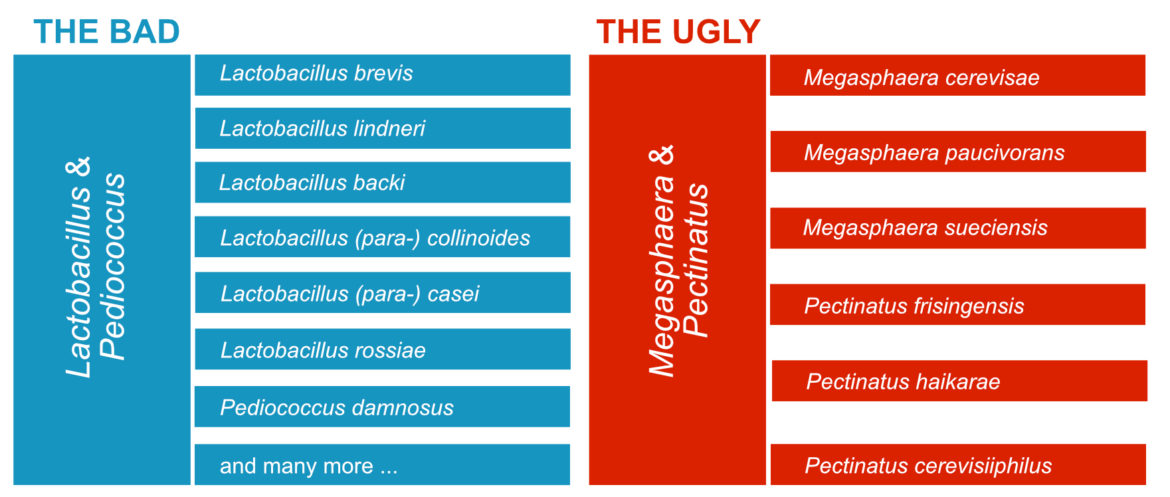

Beer Spoiling Bacteria – the Bad and the Ugly – Knowing Your Enemies

Beer can be seen as a very special ecological niche and a comparatively hostile environment for bacterial life. It is characterized by low oxygen- and high CO2 levels, a low pH, presence of alcohol and hop-compounds, as well as a lack of nutrients. But not only Jurassic Park fans know: „Life finds a way“. Of course, there are some bacterial specialists who can grow in this environment and thus affect product stability and quality.

The most frequently detected beer spoiling bacteria belong to the genus Lactobacillus and Pediococcus (The BAD). These lactic acid bacteria are gram-positive, facultative anaerobic and non-motile. The characteristic spoilage profile is determined by changes in taste, odor (sour, diacetyl) or / and texture (cloudiness, sedimentation, slime-formation). This heterogenous group of potential and obligate spoilers can occur ubiquitously in the brewery environment – as primary or secondary contaminations.

Anyone who has ever drunk a sour beer will not be enthusiastic, but it is harmless compared to contaminated beers with representatives of the genera Pectinatus or Megasphaera (The Ugly). In most cases the cloak-like odor effectively protects customers from drinking contaminated beer. This massive product damage is caused by bacterial formation of hydrogen sulfide and methylmercaptane. The typical secondary contaminants Megasphaera and Pectinatus are strongly connected to biofilms and therefore cause the sporadic contamination especially in filling area of a brewery.

Overview of the 4 Milenia GenLine Kits for the Detection of Beer Spoiling Bacteria

| Milenia GenLine Assay | Benefits of the Test System |

|---|---|

| Lactobacillus / Pediococcus - Screening | The Lactobacillus / Pediococcus screening assay is a particularly robust and easy-to-handle test system allowing specific detection of obligate and potential beer spoiling Lactobacillus and Pediococcus species - An extremely helpful and versatile tool to check colonies from solid media or "hard-to-microscope" samples, such as semi-selective enrichment cultures or yeast containg samples. |

| Megasphaera / Pectinatus - Screening | A simple and robust screening assay to confirm the presence or absence of the most feared bacterial spoilers, Megasphaera and Pectinatus. Moreover, the Swab PCR is an innovative and unique tool for rapid hygienic surface monitoring, especially in the filling area. |

| Hop Resistance Screening | This innovative test system is an excellent tool to assess the spoilage potential of an bacterial isolate of concern. This analysis can be compared to time intensive product spoilage assays, in which a bacterial, gram-positive isolate is inoculated into the existing product. There is a high probability that the spoilage ability correlates with the result of the Milenia GenLine Hop Resistance Screen. |

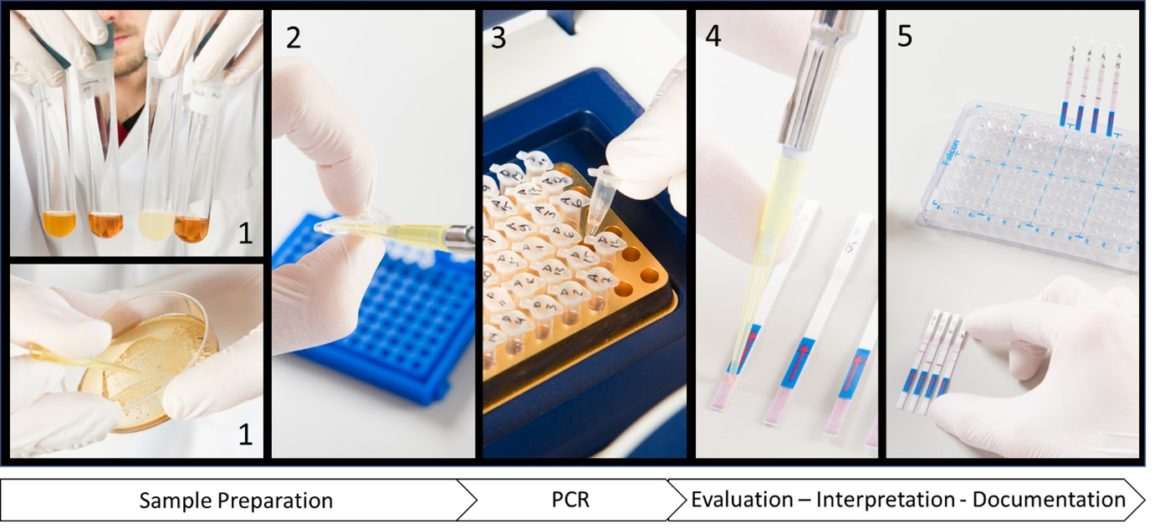

The Workflow of the Milenia GenLine Test System

The general procedure to detect beer spoiling bacteria was simplified as much as possible. Therefore the overall detection procedure has been reduced to three general working steps. The amplification cocktail is prepared by mixing two ready-to-use reagents. After the addition of the sample the reaction tubes were placed into a simple-to-handle thermal cycler. After 45 min of cycling, an aliquot of the amplification mix has to be applied to the universal Lateral Flow Device, Milenia HybriDetect. The strips were placed into running buffer and within a few minutes test and control lines appear. Results are interpretable with naked eye after 5 minutes. The total analysis time is around 1 hour, with a hands-on time of around 15 mintues.

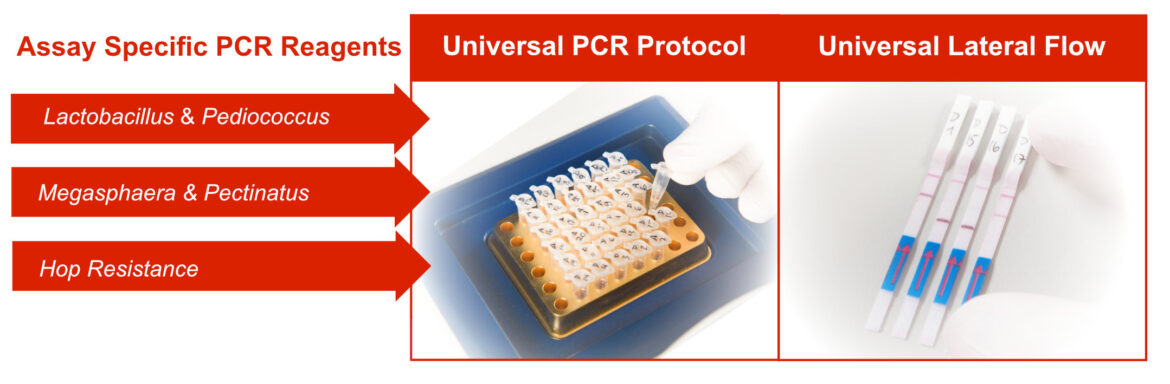

Modular Character of the Milenia GenLine Tests

The Milenia GenLine tests are dedicated to give breweries of every size the possibility to benefit from the power of molecular biology. Due to its easy-to-handle character, the test system is particularly designed to work for experienced and non-experienced users. In addition, the tests are designed to be modular, which allows the user to integrate every Milenia GenLine test easily into the lab routine.

The Detection Mechanism of the Milenia GenLine Tests?

Our assays for the detection of beer spoiling bacteria rely on our own lateral flow development platform, Milenia HybriDetect. These universal lateral flow devices are particularly suitable for methodological combination with very sensitive and precise molecular biological DNA amplification techniques. And that’s exactly what we did. We use the power of the polymerase chain reaction to enable specific, robust and sensitive analysis. The special composition of our tests allows the direct analysis of biological material directly from product, swabs or enrichment cultures. The tests are versatile and can be used individualized.

- simple: easy-to-handle and -interprete

- short hands-on-time (10 minutes)

- time to result: approx. 1h

- modular character

- not restricted to a certain number of tests

- allows direct analysis from enrichment cultures

- no DNA-extraction needed

- Controls included: internal amplification control and immunoassay control

Why should I use the Hop Resistance Screening Test?

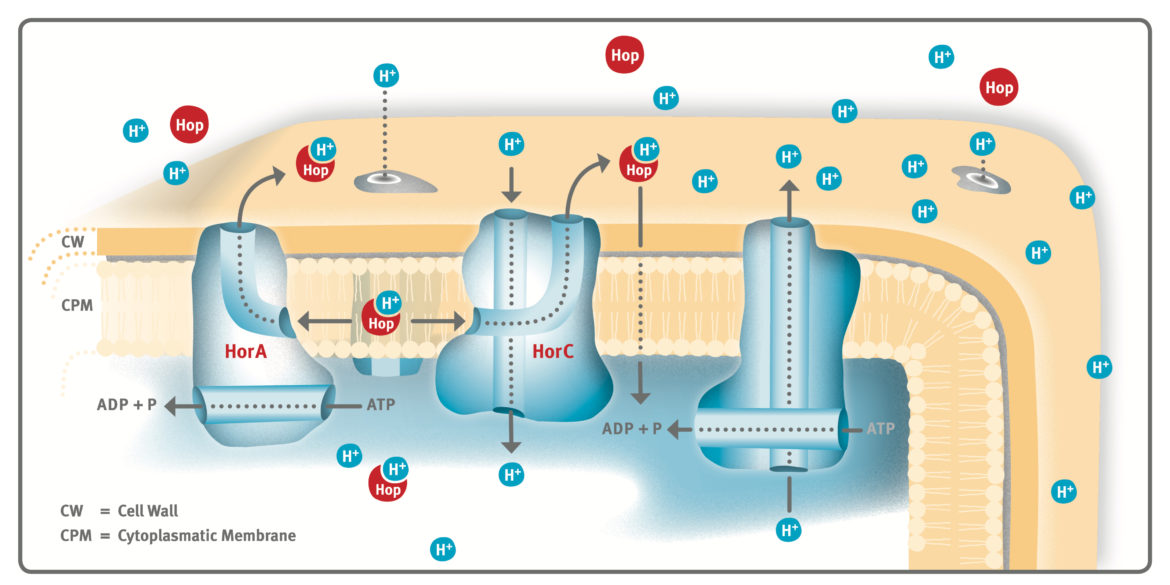

Hop has evolved to one of the key components of beer in the history of brewing. The addition of hop was originally used to protect the beer from microbiological spoilage. Especially, hop related iso-alpha-acids are very effective antimicrobial compounds against a broad spectrum of bacterial growth. Nevertheless, some bacterial species developed mechanism(s) to bypass this „growth-barrier“. Today it is known that the survival of gram positive bacteria in beer is strongly connected to the individual genetic „equipment“ of these organisms.

Bacillus (related) species in particular are characterized by great genetic variability. In adaptation to the respective environmental conditions, these organisms can acquire genetic information that enables them to survive in very special ecological niches. Therefore, genetic markers connected to beer spoiling potential of Lactobacillus spp. and Pediococcus spp. have been identified in the early 2000’s. Especially, the plasmid encoded genes horA and horC show great potential to predict the ability of a Lactobacillus / Pediococcus isolate to grow in hop-containing beers.

The Milenia GenLine Hop Resistance Screening Assay gives quick information about the presence of horA or / and horC. As a result, this simple screening test can be an innovative and helpful addition to the microbiological quality control of a brewery. The detection of at least one these lifestyle markers is a very strong indication for the presence of an obligate beer spoiling isolate.

Hygienic Surface Monitoring – Milenia GenLine Swab PCR

From a microbiological perspective, the area around the filling machine is one the most relevant areas of a brewery, because the product is presented to its environment which allows potential secondary contamination. Therefore, hygienic monitoring of the filling area is an absolutely essential part of the microbiological quality control. Biofilm formation is an exciting topic from a scientific point of view, but dealing with biofilm-associated secondary contaminations can be extremly challenging for brewers, especially when temperatures increase.

The Milenia SwabPCR is an innovative tool which allows rapid detection of beer spoiling bacteria directly from swab samples. The test system is a valuable addition to time consuming enrichment strategies especially of anaerobic obligate spoilers. It is designed and developed with brewers for brewers. In particular, the detection of obligate anaerobic beer spoiling bacteria from swab samples can sometimes be very time-consuming and thus can take days to weeks. The Milenia GenLine Swab PCR was explicitly developed to allow countermeasures at the day of the analysis.

Insensitivity beside high sensitivity – a calculation example

Many unexpienced users see PCR-based test systems as a „super-sensitive rocket-science technology“ that detects every trace of bacterial contamination. Basically, they are not so wrong. Extremely sensitive PCR-based assays are able to detect the one cell. But how beneficial is this sensitivity if only a very tiny volume can be analyzed?

The calculation example of a perfect test system: Let’s assume that the PCR-based assay is able to detect 1 cell and we can analyze 5 µL of a sample with this method. Now we see a positive result with 1 cell in our test. We are very lucky to have such a sensitive tool, but now the calculation begins…

1 cell in 5 µL corresponds to 200 cells in 1 mL. As a result, there would be a bacterial contamination of at least 100.000 cells per in 0,5 L beer. And that in turn doesn’t sound that sensitive. Just a few vital cells per container can be enough to cause massive damage to the product in a matter of weeks.

Small Sample Volume in a PCR can lead to “insensitive” Analysis

This simple calculation is intended to explain why the Milenia GenLine tests (and other DNA amplification techniques) are suitable for direct analysis to a limited extent. In most cases, it is essential to benefit from the impact of an enrichment culture in order to detect any bacterial contamination as sensitive as possible.

Possible Application of the Milenia GenLine Tests?

- should be combined with selective / semi-selectiv pre enrichment culture

- not recommended for the direct detection of trace contaminations

- can be used for direct analysis of colonies from solid media

- can be used for confirmation of a suspicion (liquid enrichment culture, colonies from solid media)

- perfectly compatible with with the NBB portfolio from Döhler Gmbh (Darmstadt)

- can be used for hygienic control of surfaces (e.g. filling area)

- tolerates comparatively high loads of background yeast

- enrichment cultures containing yeast (e.g. NBB-C + yeast beer)

- perfect for „difficult-to-microscope“ samples